Copyright 2011. figNoggle Designs.

7x10, 7x12, 7x14 Mini-Lathe Information

Website Links

Post a link to your website or view other hobby and machine and metalworking websites for free.

|

Rent Mill & Lathe DVDs at Smartflix | Great aluminum & steel prices at OnlineMetals Bridgeport Series 1 (I) J-Head Clone Full Size Knee/Turret Mill (Made in Taiwan by Jenq Shing)

We've been on the lookout for a full-sized mill for quite some time. While the ubiquitous and staple of nearly machine shop from college to fab - the Bridgeport - was top on our list, we were also open to buying a clone mill like a Wells-Index, Maxmill, SuperMax, Chevalier, Grizzly, Harbor Freight, Sharp, Acer, Alliant, Millport, Promax, Promill, Jet, and the list goes on. In essence, a mill that was in decent running condition (i.e. little rust and some signs of having not been neglected and left to rot outside the barn) was good enough for now. We had once seen a nice Maxmill (BP clone) that looked like it had been barely used (scraped ways were intact, no rust, etc..) that was local to us for an asking price of $1500. No DRO, it was a variable speed J-head series I Bp clone. The price was quite good given the condition, but we never followed up on it. Too bad! As we continued to scan eBay listings, Craigslist, and call around the various shops around, we came up with only mills that were still $1500 and above (some were clones fetching an asking price of well over $3000). These $1500 mills needed work, too. So our thinking was this. If the mill needed work, why start at $1500? Couldn't we find something for less than that? As it turns out, we had a stroke of luck. One day, while scanning the local online ads, we found one. Not much of a description, no price mentioned, etc.. So we sent out an email, followed by a phone call, which ultimately led to us checking out the mill. The pleasant surprise of all this was meeting a fellow metalworker. He had this mill sitting unused inside his shop. Clearly, from first appearances, the mill needed some work to get it running. The shop didn't have 220v 3-phase power, so we had to take his word that it worked at one time. The handles were missing, the bondo and paint job had cracked and peeled all over, and the mill in general was just dirty and the table was surface rusted (crossing our fingers that this is all!). We ended up chatting it up with the fellow selling the mill who turned out to be a cool guy and we left it there. Fast forward a few weeks(?) and we receive an email from him saying that someone else had made an offer on the mill and he was asking if were still interested. Certainly! To keep details to a minimum, we worked out an amicable deal, a deposit was made, and we took some pictures. So here we go! First of all, this mill, a clone made in Taiwan by a company called "Jenq Shing" was virtually non-existant from online searches within the US borders and beyond. This clues us in that the mill was made prior to the internet coming of age (80's?) and that the company didn't last very long or had been renamed to something else. From the styling cues of the mill, we've determined that it's a Series 1 J-Head BP clone with the step pulleys, dovetail ram, turret (no riser block), quill feed, and a few other features we're not quite familar with yet. In the picture you see below, the head's been turned down in preparation for the move.

What a beauty! (Remember, you have to look beyond the surface here and look at its potential.) And we'll take a look at the left hand side where the door is. It looks like the door to a furnace.

From this shot, you can see that under the X-axis handle is the one-shot lube system. Nice! As we take a closer look, you can see that this system uses a pull-lever pump mechanism instead of the push-style pump lever that's found in later models. Mind you, we're certainly not the authority on BPs, so if this information is incorrect, please let us know!

And for those of you who read Chinese, here's the closeup of the label:

Perhaps you can give them a call and see who answers? :) We suspect, some one else besides the company. We pumped it and we could hear some residual oil and air flush through the system. Working our way around the mill, here's a closeup of the front of the mill, or in particular, the knee.

Here you can tell that the Z-axis and Y-axis handles are missing. We should be able to find some replacements on eBay or from the usual catalogs. We're seriously considering working on a "Bridgeport CNC" project, so the style of handles may not be so important as a long-term solution. As we continue walking around the mill, let's have a look at the underside of the table:

We can see one of the lube oilers. The leadscrew seems to be OK, but until we take this apart, it's really hard to tell. There is of course some serious backlash on the order of a few ten thous. We're guessing it'll be between 10-20 thous. We can only guesstimate here since the X-axis bearing block (where the power feed had been stolen/removed) no longer existed and the left hand of the table had a loose handle. Now let's look at the ways (or what we can see from the wiping down just a bit of the thick crust of oil/dust/dirt that caked on):

It's maybe difficult to tell from this picture, but there are still some scrape marks remaining. We're probably not going to immediately send this off to be rescraped or have the mill professionally refurbished. This will do for now. Now let's look at the table. Ouch! Lots of surface rust. We didn't have a can of WD-40 or Liquid Wrench available to spray on and work the surface of the table. It appears that there aren't any major dings or drill marks - a good sign. Clearly, this surface rust needs to be addressed. We're hoping that some "scotch" pads and elbow grease is enough to remove it. Worst case, we'll take this to be resurfaced.

This is a 9"x42" table, so in the line-up of mill sizes, it's the 2nd from the largest (32", 36", 42", 48" were the table lengths available for these series mills). That makes for quite a nice work envelope. It would have been nicer to have a 48" wide table, but at 42" it's still larger than the round-column mill we have so no complaints here. All right, at this point, you might be wondering about the head itself, the motor, and labels and placards, condition of the internals, etc.. Well, here you go! This shot reassures us that the mill had indeed been housed inside. We loosend the Z-axis dial here to show what the internal portion of the leadscrew looks like:

Clean and grit/rust free. Since the head was flipped over for transport, the pictures we took were rotated 180 degrees. We hope the orientation isnt' too confusing.. Here we look at the head from the right side where the quill feed lever is (the lever's on the table):

We're actually looking forward to tramming the mill, since we can finally fine tune each axis due to the mill's axis articulation. From the top, with all its dust:

The brake works from our simple hand-rotate test. What's the lever on the right that rotates the disc? And the shot of the R8 spindle (we're assuming R8). It looks clean enough given the state of rest it's been in.

It didn't occur to us to even try extending the quill until this late in the game since the lever wasn't actually installed. But once we installed it, we pulled the lever down and the quill extended as smooth as butter. There's even oil still present. What a relief! It appears to still have quite a nice and tight fit and feel. We'll know for sure once we try some quill deflection exercises.

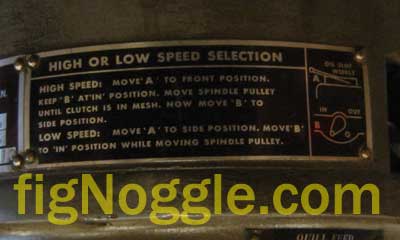

Even the labels on the head are positioned just like the Bridgeport's. In fact, the high/low placard looks identical to the Bridgeport's, no?!

And by now, you must be anxious to know who makes the mill?

Are we reading this correctly? 5440 rpm? Who wants to write these guys a letter? We're probably going to send out a postcard next week and see what happens :) And finally, drum roll please!...... This is where we find out when the mill was made!

It's difficult to see in this smaller picture, but in the original you can tell that the stamp next to the "Date" field is............ 1979! So, this mill was made as early as 1979 and could have been made even a year a so after that. Who knows. It's a 2HP motor 3-phase motor running at 220v. 6/5/5 amp draw. Design "CNS-C-229". Rotor C. This motor was made by the fine folks at Jih Chin Electric Machinery Co., Ltd. The motor even looks to be well made with a nice electrical junction box that has the company's logo cast from a cast iron cover plate. No stamped sheet metal here, folks. Think of this mill as the Taiwanese-equivalent of old "American iron".

That's it for now. We'll be posting more pictures and articles during and post-move. We'll be certain to post articles of the restoring process. We're very excited about this one! Stay tuned...

|

Looking for mini-mill help and how-tos? How about lathe help and how-tos?

We're prototyping a benchtop CNC vertical mill using the DigiSpeed-XL interface card for Mach, Dart Controls and KB Electronics KBIC/KBMM 90VDC motor controllers, 1.5HP treadmill motor from Surplus Center and a R8-spindle head from the X2 mini-mill - not to mention Gecko servo drives and an entirely closed-loop system. Come take a look!CNC 8x12 Lathe

Check out our newest developments like the CNC/DRO 8x12/8x14 lathe using Gecko drives, break-out board, NEMA 34 step motors, DRO and more!

SUPERX3.COM

Sieg X3 and Super X3 Grizzly G0463 Info

MDAHacks.com

T-Mobile MDA / Cingular 8125 / HTC Wizard Hacks, Tweaks, Tips, Tricks and More!

Metal Working FAQ.NET

Your source for metalworking and machining, tips, tricks, and more. Over 50 content wiki sites!