Copyright 2011. figNoggle Designs.

7x10, 7x12, 7x14 Mini-Lathe Information

Website Links

Post a link to your website or view other hobby and machine and metalworking websites for free.

|

Rent Mill & Lathe DVDs at Smartflix | Great aluminum & steel prices at OnlineMetals SIEG X2 MINI MILL HOW-TO Remove The Intermediate Gearset From Your Spindle Head (R8 or MT3) We purchased the spindle head for the X2 mini-mill from LittleMachineShop for the Home-Brewed CNC Vertical Mill project we're working on. As you would expect, the quality is OK and the finish is just around that. But as far as inexpensive R8 spindles go, it's a good buy. Since we're adding our own mix of motor and DC motor controller, we opted not to buy the entire assembly. We'll first take a "walk-through" of this unit.. Here we have the front of the head. We already removed the plastic chip guard base and what do you know? Sieg must have rushed getting this out since it looks like the painted hadn't even dried before slapping the base on:

Nothing fancy here. Now we'll look at the right side:

What's difficult to see here is the special paint technique used in the factory. It's kind of like that painting technique for your home walls where you paint and the then immediate dab crumpled newspaper to create a textured effect. Neat! :) And now we'll take a look at the other side:

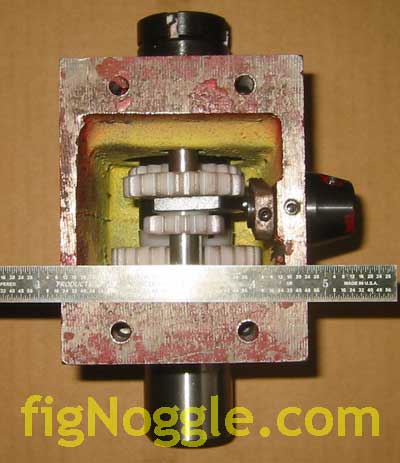

Here you can see a bit of that special painting technique we just mentioned.. OK, now for the fun stuff! Let's first give you a shot of the guts of the head; the intermediate gears (or the high/low gears):

The basic mechanism is a fork-lever that pushes/pulls the gear assemly up/down to engage and disengage. It's locked in with a key and slides freely. BTW, this is is one of the parts that can fail when you drive your mill too hard. Let's hope that most of us only have the gear sitting at the top of the head break since getting into this head requires removing the entire assembly and removing the other part of the head, motor, controller - what a mess! If this does happen, you can always do the belt drive upgrade. Our method is quite easy and can be done with a drill press and lathe (only to cut the keyway, not to make pulleys). Before we forget, the unit weighs in at around 13 lbs. It certainly has some heft to it for such a small mill. Alright, now let's remove this gearset. Firstly, you'll need some hex wrenches, pliers for removing circlips, and an arbor press (preferred). That's it! We'll remove the set screw that holds the gear lever base in place:

Next, we'll remove the set screw that holds the internal fork/lever arm to the base:

That was easy! Once you've done that you'll end up with these parts:

You can barely see it in this picture, but there's a little ball bearing and spring that you can remove simply by pushing it through with a paper clip or small screwdriver. They're located on the left side of the now-empty hole. Here's where the circlip plier comes in handy.. We now need to remove it from the bottom of the head since it holds the gearset spindle in place:

Once this is removed, the hard part's here.. removing the gearset spindle from the bearings and head. You'll of course want to push this end of the spindle through. You can use a hammer to bang on it but that's not recommended. Just slip the head under the arbor press and push!

By now, the spindle and top bearing should drop out. Next you'll want to flip the head over and remove the bottom bearing (shown here). Stick something like a socket extension in there and use the arbor press to push it out. Here are all the parts to the gearset:

Notice that the circlip plier didn't have the original attachments so we used piano/spring wire instead. Works just fine! That's it! |

Looking for mini-mill help and how-tos? How about lathe help and how-tos?

We're prototyping a benchtop CNC vertical mill using the DigiSpeed-XL interface card for Mach, Dart Controls and KB Electronics KBIC/KBMM 90VDC motor controllers, 1.5HP treadmill motor from Surplus Center and a R8-spindle head from the X2 mini-mill - not to mention Gecko servo drives and an entirely closed-loop system. Come take a look!CNC 8x12 Lathe

Check out our newest developments like the CNC/DRO 8x12/8x14 lathe using Gecko drives, break-out board, NEMA 34 step motors, DRO and more!

SUPERX3.COM

Sieg X3 and Super X3 Grizzly G0463 Info

MDAHacks.com

T-Mobile MDA / Cingular 8125 / HTC Wizard Hacks, Tweaks, Tips, Tricks and More!

Metal Working FAQ.NET

Your source for metalworking and machining, tips, tricks, and more. Over 50 content wiki sites!