|

Rent Mill & Lathe DVDs at Smartflix | Great aluminum & steel prices at OnlineMetals

X2 CNC CONVERSION PLANS

| X2 CNC Conversion Plans |

|

BUY NOW

$39.95

|

|

INTRODUCTION

The Sieg-built X2 mini-mill is quite a capable little machine.

While manually machining is fun, converting the machine to CNC (computerized numerical control) operation is even better. CNC machining allows you to design the part on the computer and tell the mini-mill to machine it for you.

But what if you wanted the best of both worlds?

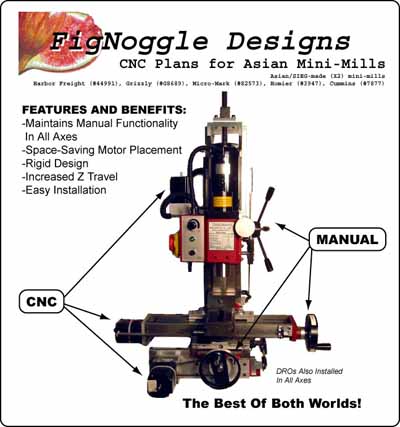

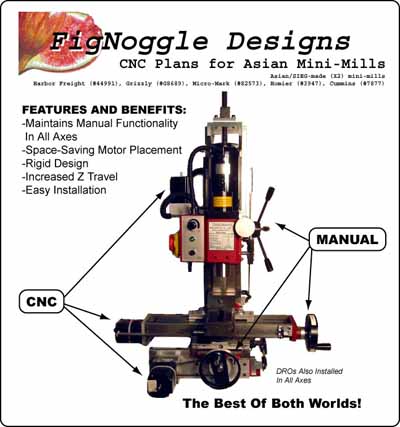

Our design maintains FULL manual functionality. This is important since there are times when a simple part must be made and manually machining that part takes much less time than with setting up for CNC.

With this CNC conversion, you will be able to machine 2D contours and complex 3D contours that you would not have been able to do previously. You can then switch back to manual mode without changing a thing!

Coupled with a DRO setup, you can now use your machine just as accurately as you can with CNC.

What is CNC? And why do I need it?

If you have ever wanted to machine a part that had radii or complex contours, you'll know that it's almost impossible to do so with repeatability and quality not to mention in a timely manner.

With CNC, the computer and machine work together to make your part based on a design in your computer.

Imagine a part with multiple holes that needed to be drilled. With CNC, this would all be automated. Peck drill at will!

How about that large diameter hole you wanted to machine? You could use a boring bar or rotary table, or tell the computer to machine it out for you.

Now, for complex shapes. You want to make a mold from wood, plastic, metal. You design it in the computer and have the mini-mill machine those complex 3D contours for you. You'll end up with a mold you can use over and over again.

So what are we offering?

figNoggle Designs is offering plans (72 pages in all!) to instruct you on how to build the mounting hardware for the CNC conversion. There are tons of pictures and instructions, CAD drawings of each part to make as well as a materials list with part numbers, vendors, and pricing. Basically, this set of plans will help you get your CNC conversion installed on your mini-mill.

(actual pages from the plans - 72 pages in all!)

Plan/design features:

- Maintain manual use! No switching hardware needed.

- Works in both CNC and manual mode.

- Our design is space-friendly

- No limitations in travel in all axes

- Rigid design

- Easy installation

- Provides vendor sources and pricing

- 72 pages of easy-to-understand written instructions, pictures, and CAD drawings!

- Available in PDF format for quick delivery to your email account

- Works with the figNoggle Designs' DRO plans

figNoggle Designs' CNC conversion plans work with the following Sieg X2 mini-mills:

- Harbor Freight 44991

- Grizzly G8689

- Micro-Mark 82573

- Homier 3947

- Cummins 7877

How long does it take to make?

It takes anywhere between one to two full weekends. Also, since pricing varies greatly, we have suggested the most economical parts and vendor sources to get you going. All parts are machined with only one (1) piece of flat stock and one (1) piece of round stock and one (1) block!

What are the terms of sale/use?

We accept any form of payment PayPal uses as we process online orders via PayPal. We will also accept check or money order. Please email us for more information.

We do not accept returns. Plans are sold as-is with no warranty. We assume no liability for contents in the plans.

Once we receive confirmation of your PayPal payment, we will send you the PDF file (approx. 5mb) to the email account shown on your PayPal account or the one you use to pay with. If you have special instructions, please email us first!

Note! Please check if your email account can handle a 5mb file. We may also be able to break up the file in two pieces to facilitate email transmission should this be a problem.

Plans are intended for personal/hobby/learning uses only. Kits made from our plans for commercial purposes is prohibited.

Your email address will be stamped on each page of the plans in order to help prevent unauthorized distribution.

Your email address and personal information is held strictly confidential. We will not share, sell or do anything with your email address.

(Watch a 30s video of the X, Y, Z axes doing a 1" jog. Stock leadscrews with brass nuts modified to reduce backlash. Results are after 5 minutes of adjusting mill. Average accuracy is 0.001") CLICK HERE TO VIEW.

|

X2 CNC Conversion Plans

|

|

BUY NOW

$39.95

|

|

Questions? Please email me at david at/at fignoggle dot/dot com.

Click Here To Download Acrobat Reader

|